WHAT IS EXPANSIVE MORTAR?

EXPANSIVE MORTAR Non-Explosive Demolition Agent is a non-toxic and cementations powder, which consisting of calcined oxides of calcium, silicon and aluminum, EXPANSIVE MORTAR becomes a highly powered amazing expansive pressure of 11200 T / m2 when mixed with water. Marble, granite, limestone, plain concrete, reinforced concrete, boulders, and ledge are fractured overnight without noise, vibration, or fly rock. Especially, used as environment constraints or when explosive is not permitted for use.

HOW DOES EXPANSIVE MORTAR WORKS?

It develop rise of highly expansive capabilities at the consistent volume exceeding 122 Mpa ( 11200 T/ M2) more than enough to break up any materials to be cut or demolished. The tensile strength for most rock is less than 5-25 Mpa (500-2500 T/m2 50-250 kg /cm 2), Reinforced concrete breaks at 3-5 Mp (30-50 kg /cm2, 300- 500 T/ M2).

WHAT IS EXPANSIVE MORTAR USED FOR?

1.Quarrying marble and granite, limestone, sand stone; cracking nature ground

2.Breaking rock into pieces; deposition of falling rocks

3.Demolishing concrete structure, Chipping defective concrete piles, etc

4.In the field as a new method of demolition, EXPANSIVE MORTAR can effectively be use in the construction and civil engineering fields as follows:

Bridges Dams

Ledge Boulders

Machinery Bases Concrete Piers

Slabs 6" thick and more Marble and Granite

WHAT ARE EXPANSIVE MORTAR ADVANTAGES AND BENEFITS?

1. No licenses or permit required

2. 2 year shelf life

3. One product available for all temperature

4. Use in safe, no noise, vibration, or fly rock,

5. Easy to use, no need of train.

6. MSDS available

TYPES AND PACKING OF EXPANSIVE MORTAR

There are three types of Expansive mortar for traditional type, depending on usable temperature,

Type of EXPANSIVE MORTAR Usable temperature

SCA-1 25°C-40°C ( 77°F-104°F)

SCA-2 10°C-25°C ( 50°F-77°F)

SCA-3 -5°C-10°C ( 23°F-50°F)

Universal type: one product for all temperature

Packing: powder by inner plastic bag, 5kg / bag, 20 kg / carton, one ton / wood pallet

Form: powder and cartridge available

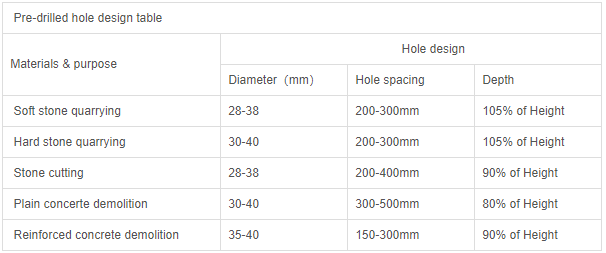

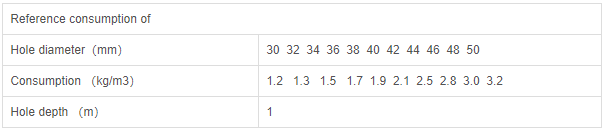

EXPANSIVE MORTAR Technical manual.pdf , covers cracking design (hole depth, hole pattern,), drilling, mixing, filling instructions, estimating consumption quantity, cracking time, cracking gap.

STANDARD QUANTITY

Drilling

Drill holes designed for demolition with a drilling machine.

(1) Drilling machine : Jack Hammer, Leg Hammer etc.

(2) Drilling Direction : It is preferable to drill holes vertically, but in case of a wall or pillar of reinforced concrete where vertical drilling is hard, an inclined hole may be drilled. For horizontal holes, the same idea of spacing as with vertical holes can be applied. Try to drill horizontal holes with some slope.

(3) Drilling machine : Use of Spiral Sheath Pipes

In the case of a temporary concrete structure (to be demolished), place spiral sheath pipes as holes before placing concrete. When the structure needs to be cracked, fill the holes with SPLITSTAR® expansive mortar after removing the spiral sheath pipes.

There is no change in breaking effect by the use of spiral sheath pipes. However, spiral sheath pipes of 36-50mm (1 3/8"-2") diameter should be used.

NOTE : Never use vinyl chloride pipes etc. instead of spiral sheath pipe. Leg Hammer Spiral Sheath Pipe

SAFETY PRECAUTIONS

1. Wear safety goggles, rubber gloves, long sleeve cloth and helmet during expansive mortar handling, mixing and filling.

2. Do not get your face close to or stand near filled holes for at least 3 hours after filling completion stop the hurt to eyes in case of blow out shots.

3. Wear a dust-proof mask when using expansive mortar in poorly ventilated areas such as tunnels or mines.

4. Keep people away from job-site after filling mortar.

5. Skin contact with expansive mortar must be rinsed off with large amounts of cold water immediately.

6. Should you get spray from expansive mortar in your eyes, do not rub but wash the eyes immediately with plenty of cold water and consult doctor.